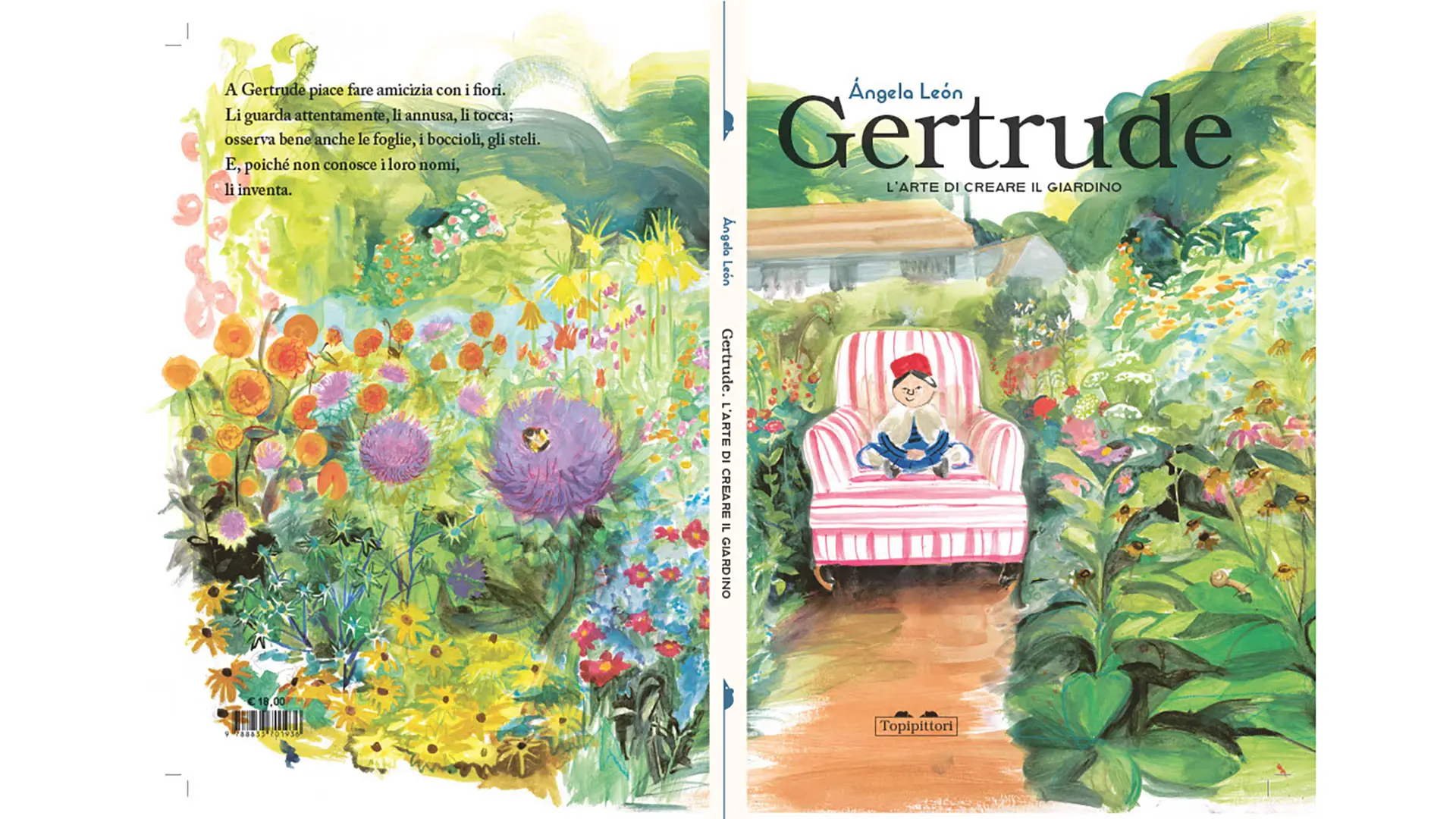

Gertrude. L’arte di creare un Giardino [Gertrude. The Art of Creating a Garden] by Ángela León, published by Topipittori, has just been released. It is the third in a series of books dedicated to extraordinary women who have changed the way we live and inhabit

Sustainability: the furniture industry reports back

De Castelli Production, ph. Mattia Balsamini

Traceability, welfare, circularity, as well as art and culture: Arper, De Castelli, Florim, Flos and Pedrali present their points of view

Best practices, put down in writing. A sustainability report is a declaration or account – usually less structured than a financial statement, with a more narrative and communicative approach – that is not limited to business aspects, but includes environmental impacts (such as emissions, energy consumption, resource use), social initiatives, and governance practices – encompassing topics such as ethics, transparency, and risk management. Here are the furniture companies that have decided to share their best practices.

Arper’s strong metrics

Extremely detailed in its reporting of metrics, internal surveys, and measurable objectives, Arper’s 2024 Sustainability Report provides a structured overview of the company’s commitment to environmental, social, and governance responsibility. It’s no coincidence that, since 2021, they have a dedicated Sustainability Office reporting directly to the CEO, translating strategic priorities into concrete action plans and performance indicators. The Office is also supported by an internal Environmental Department and a network of sustainability ambassadors across company functions.

The report highlights the company’s focus on secondary raw materials and low-impact alternatives, guided by the internal Ecodesign Charter focused on waste prevention, material reduction, and design for disassembly. Initiatives such as sustainable mobility and the “Packaging 2.0” project address key Scope 3 critical issues – i.e. indirect emissions generated along the entire value chain – helping to strengthen the company’s resilience in the face of regulatory evolutions and market changes. From an environmental perspective, Arper has also developed an advanced system to ensure the quality of incoming materials and to facilitate their regranulation and reintroduction into the production cycle, favouring open-loop recycling models.

As regards the climate transition, compared to the 2022 baseline, the Group is committed to a 42% reduction in absolute Scope 1 and Scope 2 emissions – direct emissions generated by company activities and indirect emissions related to purchased energy, respectively – and to a 25-42% reduction in other supply chain emissions, known as Scope 3, by 2030. In addition, Arper is taking action for the progressive replacement of virgin aluminium and steel with certified secondary materials and the launch, starting in 2027, of a take-back pilot project on selected collections.

The expected results in terms of the circular economy are also interesting: if the company achieves its targets, it will reduce demand for plastic and virgin metals by approximately 400 tonnes between 2025 and 2027 and avoid the disposal of approximately 100 tonnes of product and packaging waste annually once the take-back system is operational. On the social front, the report provides detailed data on diversity, training, skills development, work-life balance, and the protection of human rights.

Finally, ample space is dedicated to Catifa Carta, a project that epitomises Arper’s strategy and represents an ambitious step to align design excellence and environmental responsibility. The chair features a shell in PaperShell, an innovative composite material made of layers of FSC-certified kraft paper and 100% biogenic resin, obtained from recycled by-products from sawmills in Sweden and Finland. In addition to its renewable origin, PaperShell stands out for its density and durability, enhancing its carbon sequestration potential. Compared to the Catifa 53, made of fossil-based plastic, Catifa Carta has a significantly reduced climate footprint and, in certain end-of-life scenarios, opens up the possibility of carbon-negative solutions thanks to the stable storage of biogenic carbon.

Arper, Catifa Carta, ph. Salva Lopez

De Castelli, transparency counts

De Castelli has chosen to become a Benefit Corporation and to begin the process of obtaining B Corp certification this year. Late last year, it presented its first Sustainability Report, a document that, as explained in the accompanying note, aims to confirm the brand’s commitment to the values that have guided the company for four generations, reinterpreting them in light of contemporary challenges. The Report describes De Castelli’s identity and values, governance, and approach to environmental and social sustainability issues, from climate change to welfare, and cultural commitment.

Regarding governance, during the year under review, a transversal ESG working group was established between De Castelli and its parent company, Etere, with the goal of proposing and developing projects in various areas of expertise, involving colleagues in day-to-day operations, and increasing skills through training activities and dialogue with other corporate entities.

Considerable attention is dedicated to the topic of energy, with a view to contributing to the European Union’s “Net Zero” goal by 2050. Efficiency, electrification, and the transition to renewable sources are the cornerstones of the ongoing decarbonisation process. As 2024 marked the first full year of operation for the company’s photovoltaic system – installed between 2022 and 2023 and restored after damage in 2023 – self-generated energy increased by 70%, while self-consumed energy increased by 100%. In the year under review, photovoltaic systems covered 37% of the company’s electricity needs, compared to 24% the previous year.

The Report also adopts a highly transparent approach in its analysis of raw materials: for example, it states that consumption increased in 2024, consistent with revenue growth and procurement strategies. In addition, more efficient planning of sheet metal cutting has reduced waste to under 15%. Chemicals were managed in order to keep inventory levels below 1,000 kg, with benefits in terms of safety and reduced environmental risks. The DeGreen Pack project was launched to reduce packaging’s total weight and replace plastic with sustainable and certified materials.

In 2024, waste produced was more than double the volume of materials produced and recorded a 40% increase compared to 2023, mainly due to the effect of the CER 11.01.12 standard. This refers to the water used in the DeLabrè finish department to dilute acids and rinse treated surfaces. Given this data, investment in a treatment and recycling plant is planned for this year, which will reduce waste volumes by 95%.

The report concludes with a commitment to local culture: support for the CombinAzioni Cultural Association and the 2024 inauguration of the garden Arena, as a stage within the company premises open to the community and dedicated to cultural and social events.

De Castelli Production, ph. Mattia Balsamini

Florim, focus on the environment and society

Florim has long stood out for its transparent and structured approach to environmental and social issues. Last October, the company renewed its B Corp certification, confirming its concrete commitment to sustainability throughout its supply chain. The first ceramic company in the world to achieve this recognition in 2020, last year Florim further improved its consolidated score.

One of the most important chapters of its Sustainability Statement is dedicated to environmental responsibility, symbolised by the green colour of the “L” in the company logo. In terms of products, Florim porcelain stoneware is made from over 90% natural raw materials; suppliers are monitored using dedicated software that takes into account quarry location, distance from the factory, recycled content, and safety data sheets. Since the end of 2022, the company has also initiated a process of reducing the thickness of its slabs, with significant sustainability benefits.

Florim’s Sustainability Statement also delves into projects such as Carbon Neutral Surfaces, developed to neutralise unavoidable CO₂ emissions generated by production and the product life cycle through offsetting projects, and Responsible Packaging, which has led to the elimination of plastic from sample packaging, which is now recycled and recyclable, and the replacement of traditional materials with more sustainable solutions. Another relevant project is CeramiCycle, which, in collaboration with the Civita Castellana sanitaryware ceramic district, promotes a circular economy model through the recovery of third-party ceramic waste. Since 2012, Florim further measures the amount of CO₂ emissions avoided thanks to self-produced energy from photovoltaic systems and the use of energy from certified renewable sources.

Finally, the Sustainability Statement focuses considerably on social responsibility: from the Florim 5.0 Master’s, which involves young high school and university graduates in a structured training programme, to the Learning digital platform. Alongside corporate welfare, the company promotes local welfare initiatives such as the “Water is Life” project with the non-profit organisation Rock No War, which supports water projects across the world. Last but not least, the report features the Health and Training Centre developed in collaboration with the Hospital in Sassuolo, now equipped with a 3D design and printing lab for customised prosthetics and prototypes, inaugurated in 2024, and the Florim Gallery, renovated in late 2025 to express the company’s ongoing commitment to culture and to dialogue with the art world.

Florim Headquarters in Fiorano Modenese (MO, Italy)

Flos, a concrete report

In its latest Sustainability Report, Flos paints a picture of sustainability as a concrete practice, intertwined with production, design, and risk management. A personal and dramatic note emerges from the document: in October 2024, a severe flood hit Valencia, home to the group’s Architectural activities, causing a temporary halt in production. Operations restarted by the end of November thanks to a rapid recovery plan, but the event made the effects of climate change tangible, strengthening the company’s commitment to resilience and proactive risk management.

Starting from this, the report highlights how the supply chain requires flexibility, due to fluctuations in both the demand and the availability of raw materials and components. Suppliers are therefore chosen according to geographic proximity: 68% are based in Spain, and approximately 37% operate in the Valencia area. To ensure high standards, Flos incorporates clauses regarding safety, environmental impact, and working conditions into its contracts, reserving the right to request detailed data and conduct environmental and social audits.

The company’s sustainability strategy is based on three pillars: Energy and Materials, Development and Wellbeing, and Heritage and Know-How. On the environmental front, objectives are clear: 27.5% reduction in emissions by 2030, 100% electricity from renewable sources by 2026, disassembled and recyclable components accounting for at least 80% of new products and the exclusive use of recycled or organic textiles since 2023.

Given these targets, design and industrial choices are geared towards a transition to a low-carbon and circular economy. This motivates the collaboration with associations such as Assoluce and Lighting Europe, to contribute to the development of standards and regulations, particularly regarding safety and advanced LED technologies. Some products embody this approach: SuperWire features custom LEDs and a chrome-free glass and anodised aluminium structure, designed to be disassembled and remelted without loss of purity; Bellhop Glass, made entirely of blown glass, is designed to be disassembled by hand without glue, facilitating end-of-life recycling. In 2024, Flos also reached a symbolic milestone: 100% of the new products in the Decorative Collection use recycled textiles.

The report also discusses the Bernareggio plant (near Monza, Italy) for the Outdoor collection, where investments in energy efficiency, water treatment, and chrome-free paints have reduced consumption and environmental risks, completing the elimination of chromium-based processes by the end of 2024. On the materials front, the progressive replacement of polyurethane with cardboard packaging has led to an 83% reduction in foam purchases compared to 2013.

Finally, it’s worth mentioning the section dedicated to the Flos team: in 2024, the company provided over 4,100 hours of training. Alongside lean manufacturing, investments were made in advanced technical courses for designers and collaborators, covering everything from regulations to lighting applications in residential, museum, or hospitality settings. This is a way to bring together innovation, expertise, and the wealth of know-how that remains one of the brand’s most valuable assets.

Sustainability

Sustainability