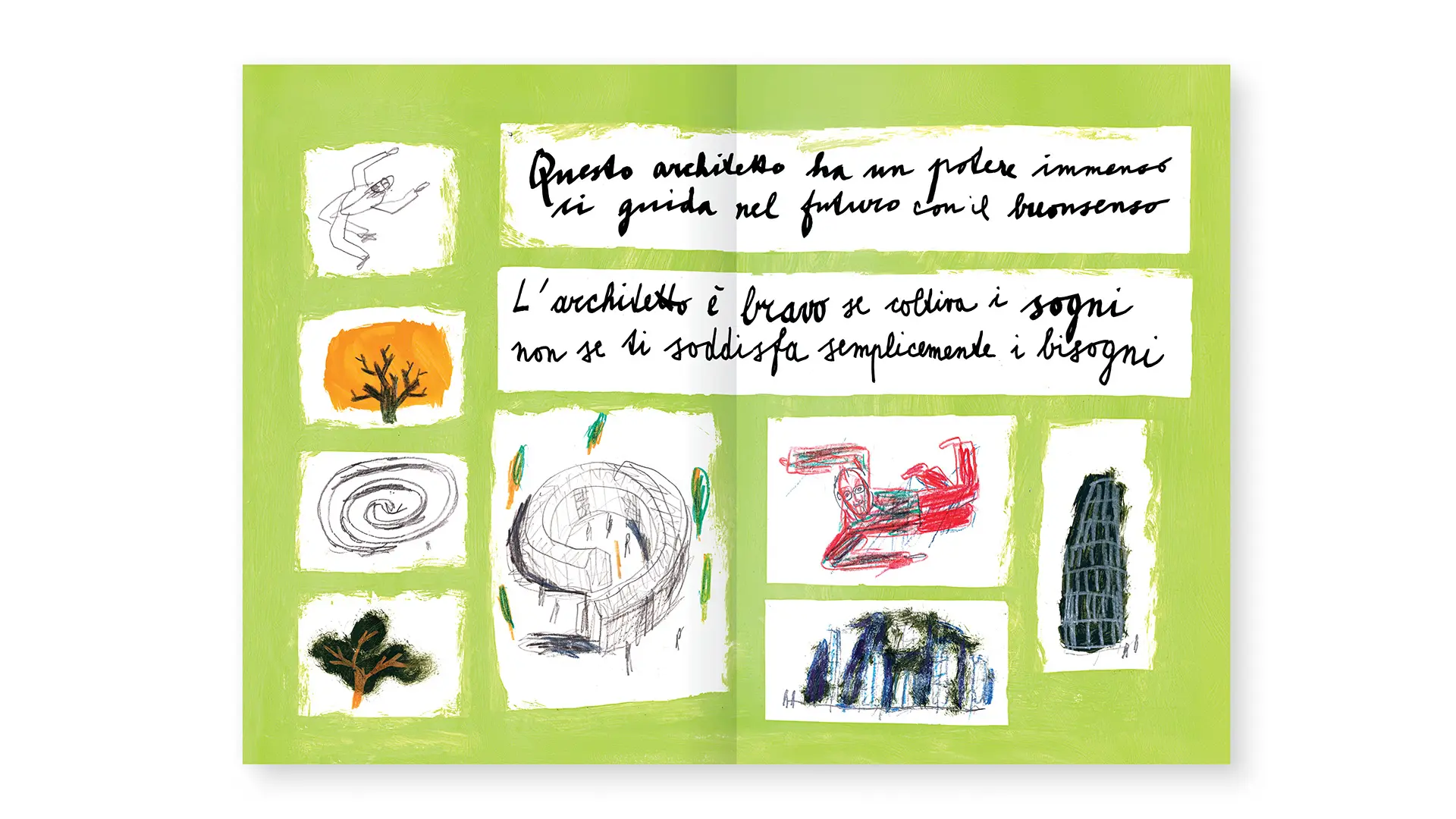

Some children’s books go beyond wonderful illustrations and clearly deliver a strong message. The titles in this selection invite young readers to look at the world with the eyes of great architects, dream up incredible homes, find lost things. Why? To learn a truly meaningful skill: the ability to recognise the beauty around us, and to understand how to take care of it

Francesco Meda: “My design? I never start with a shape in mind”

The Milanese designer focuses on design geared to purpose, less trend-led. He also explores art-design and self-production and takes his own particular approach to materials.

His visionary feel for the contemporary and his passion for the history of design saw him appointed creative director of the Acerbis brand in 2020, along with the Spanish designer David Lopez Quincoces.

Born in 1984, he studied Industrial Design at the IED in Milan, the city where he was born, before moving to London. He spent two years there, working in the studios of Sebastian Bergne and Ross Lovegrove. On his return to Milan, he started working with Alberto Meda, his father.

Meanwhile, he also explored art/design with other companies and galleries, such as Nilufar and Rossana Orlandi, Mint, and the Schoeni Art Gallery in Hong Kong. His collection Orme Cinesi was exhibited at the Lane Crawford department store in Hong Kong, and later at the Schoeni Art Gallery in 2012-13 during the Hong Kong Art Fair.

He began to produce his own work in 2013, making LED lamps, marble tables (his favourite material), benches and 3D-printed jewellery. The latter, along with the Bridge lamps, are now in the Triennale Design Museum collection.

Also in 2013, he and Alberto Meda designed the Flap acoustic panel for Caimi Brevetti, which netted the 2015 German Design Award, the Design Europa Award and the 2016 Compasso d’Oro. They won the 2016 Best of NeoCon Silver Award for their Sipario modular sound-absorbing system, again for Caimi Brevetti. Francesco Meda’s ash chair Woody for Molteni & C. won the 2019 Wallpaper Design Award.

His stand-out quality: a particular approach to materials filtered through a fluid and essential language.

Woody by Francesco Meda for Molteni & C.

I hope companies and designers would be more sensitive when it comes to developing products that respond more fully to real needs and that they would use production processes, given that not all materials are finite. The kind of design aimed at things people actually need, and less focused on products that follow the “trends.”

I would describe my current and my future studios as “digitised Renaissance workshops.” At the moment, my father and I share the studio. We also adopt a workshop rationale as regards the “transfer of knowledge,” but also take a powerfully contemporary approach to innovation, in terms of technologies such as 3D printers and scanners and parametric software that enables us to analyse every single part of the design process.

Working in the studio with my father has been a great boon, because before I joined him in 2008, he had always worked on his own. I worked as his assistant for the first few years. It was like a fast-track Masters!

Our business is like a “workshop,” there’s a transfer of knowledge. Now we each work on our own things, and every so often we do something collaborative.

It’s a very stimulating interchange because it gives my father a chance to look at the world through a young person’s eyes. The working relationship between father and son is always very delicate, but underlying it all there’s the respect and generosity of a father who has never been stood in my way, on the contrary he’s been very direct, sincere and hugely stimulating.

Aledin by Alberto and Francesco Meda for Kartell

London was a seminal experience because it enabled me to witness two very different set-ups. Sebastian Bergne’s studio was very small, we were two collaborators and we worked on very different projects. We designed for large brands but ,that notwithstanding, Sebastian was one of the first designers to pursue the concept of self-production.

This experience helped me understand how to create a product without the backing of a company. We designed, we made prototypes, we looked for suppliers, we produced small batches and we also had to deal with the communication and distribution side of things. It was a 360° lesson in understanding the life and production cycle of an object.

Ross Lovegrove’s studio, was highly structured, with 12-15 collaborators, and we worked with the leading brands. Some of the projects were visionary ones for the time – concepts for vehicles fuelled by solar panels, wind turbines, lamps using OLED technology etc. It was a laboratory of innovation and Ross always inspired us to ratchet up the level of experimentation. It was a hugely important experience on a human level too because I learned to work as a team with people from different cultures.

I decided to come back to Milan because I asked my father (who had always worked on his own) if he wanted an assistant! It was a huge opportunity for growth … and also an opportunity for exchange and comparison for my father, given that I introduced him to 3D design, which I’d learned about while I was in London.

His particular character enabled us to build up a relationship based on mutual respect, and this attitude meant that we are still sharing the same space today. Each with our own clients, but we often work on things together.

I was fascinated by the idea of using such a noble yet heavy and fragile material. I decided to carve the Pigreco stool from a block using a diamond blade. I discovered that the company I was working with, Henraux, a leader in the coverings sector, produced a lot of waste material, so I decided to create a block made up of lots of marbles, a sandwich of layers. The resulting object generated a new and unexpected sort of look. I was fascinated by the colour of these marbles and by working with the slabs, and decided to design tables that responded to the current demands of clients. I couldn’t make heavy, immovable tables that couldn’t be taken apart, so I decided to split the slabs in two – hence the name, Split – and hold them together with a brass profile that highlights the division. The metal supporting structure allows the legs and slabs to be fixed in situ.

Pigreco by Francesco Meda for Luce di Carrara

I never start with a shape in mind because I believe designs come together as you go along, within the constraints of the material and the technology being employed. I always try to use as little material as possible, and this approach makes for a “calm” look that doesn’t “jar”. The issue of the relationship between the components is extremely important because it determines an attention to detail and an organic approach to the juxtapositions. Nature is an extreme example of the elegant integration of parts.

When I think about a product, I have to take a flexible approach to its many potential facets and to its variety of uses. One always tries to create a product that allows for flexibility both from the company’s point of view and from that of the end client. Flexibility, along with customisation, allows for different material configurations that generate different looks, as in Sistema XY: wood makes for a warmer look, stainless steel makes for a more industrial and technical one.

In this particular case, the brief from Dada was clear-cut: to design an accessorised system that would go with all the kitchens in the catalogue. The main problem was coming up with a functional and cross-cutting product that could be created using a simple, non-invasive method of construction, so that it would slot seamlessly into the existing kitchens. I started by envisaging a new type of use for the kitchen, achieved through the integration of different accessories.

Sistema XY develops vertically and horizontally by means of different extruded profiles that allow the shelves to slide (vertically) and horizontal profiles onto which the accessorised sinks are mounted. Making all the different profiles was complicated because they combine different functions and must not look invasive, equally they have to be structural elements that hold up the entire system. I worked a lot with the technical department to define aesthetic and structural details. It also proved hard to make for easy assembly, because the system is made up of numerous components that have to “dialogue” with each other, like in a machine.

Sistema XY by Francesco Meda for Dada - Photo by Tiziano Sartorio

My relationship with my father, a designer/mechanical engineer, is without doubt the most stimulating thing because it gives me access to specific knowledge in terms of techniques and processes, but more importantly he has really helped me to nurture a constructive, rather than a formal, approach to design. Flat (a sound-absorbing panel) is an example of a project carried out by two pairs of hands, in which two different approaches come together – mine is more graphic, his is more technical – to try and work out the hinge mechanism that allows the panel to be turned in different directions. The combination of approaches informed an extremely decorative product, which is also technical and functional and solves the problem of sound pollution inside spaces such as restaurants, schools, hospitals and other public places. This is an example of a project carried out by two pairs of hands in which the intergenerational exchange has conferred added value in every sense!

Getting closer to the International Bathroom Exhibition 2026. Interview with Elia Vismara

Towards the 2026 International Bathroom Exhibition: Elia Vismara, President of FederlegnoArredo’s Assobagno, outlines the new trends and technological developments that will transform the bathroom environment in the coming years

Stories

Stories